Our biogas project was successfully commissioned

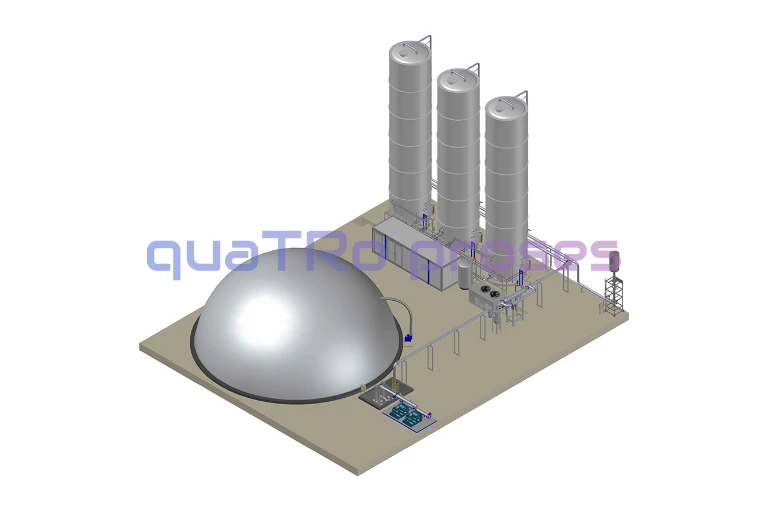

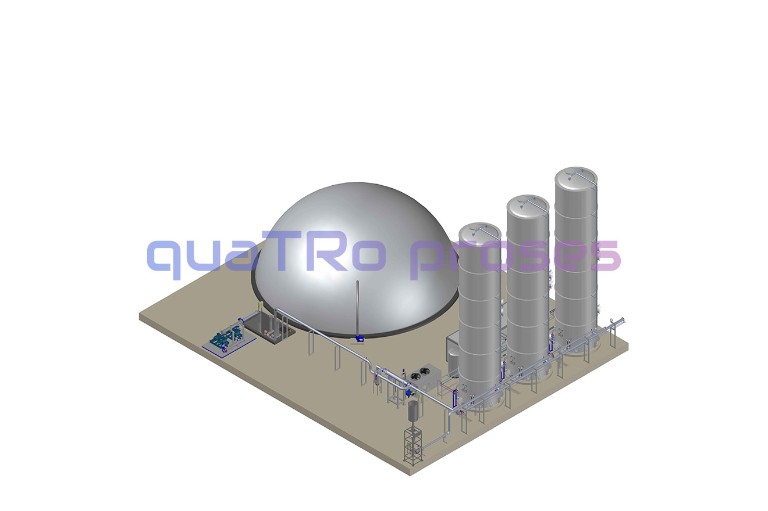

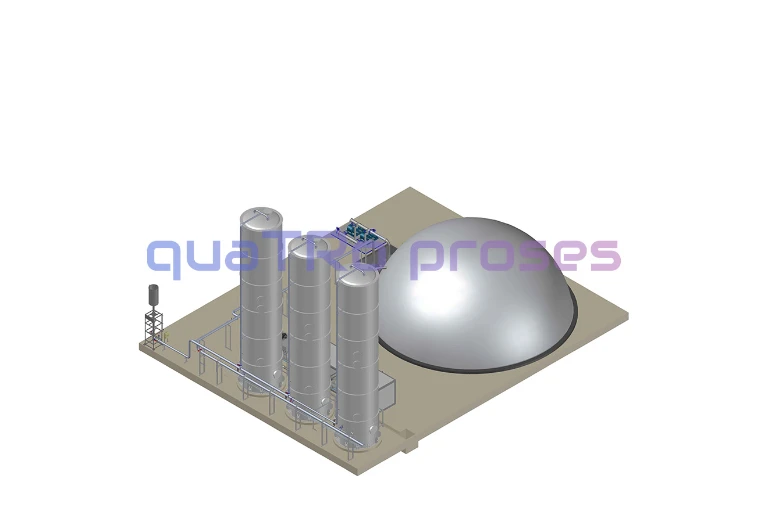

Our biogas system, which includes the processes of treatment, dehumidification, storage, and pressurization of biogas with high hydrogen sulfide (H₂S) content produced from pulp and paper wastewater treatment plant sludge for burning in the boiler, has been successfully commissioned.

In our biogas project, we aim to burn biogas at a rate of 1,000 cubic meters per hour in the boiler that meets the hot water and steam needs of the factory. This will reduce the natural gas supplied from outside.

In our project, where hydrogen sulfide (H₂ S) gas is expected to reach up to 10,000 ppm values, desulfurization below 200 ppm level was achieved in the outlet gas with three biological desulfurization towers. A double-membrane biogas storage balloon with a volume of 1,000 m³ was used to store the gas.

The quaTRo process dehumidification system was employed for the cooling and condensation of biogas. In the dehumidification system, the inlet gas temperature of 40°C will be reduced to 7°C using a shell-tube heat exchanger.

To reach the required pressure (300 mbar) to efficiently combust the biogas in the boiler, multistage biogas blowers are employed. The blowers are driven by control panels that are proportionally controlled by pressure sensors.

In the event of emergencies and high flow rates, a gas flare is utilized to combust the gas.