Big bag discharge system have been shipped

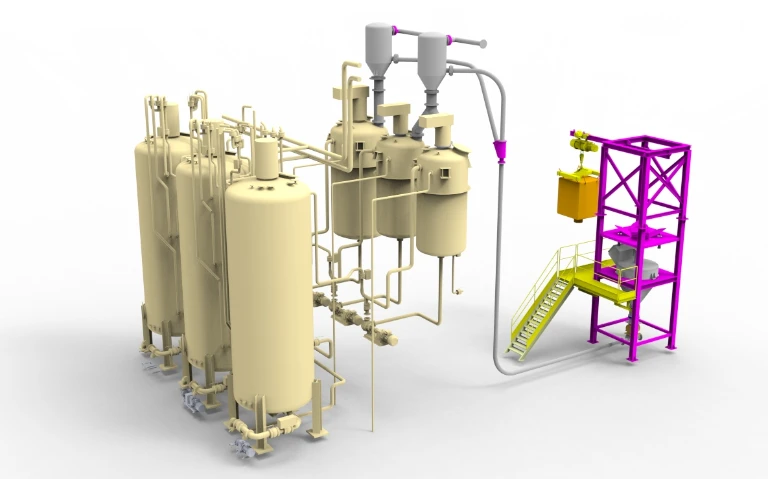

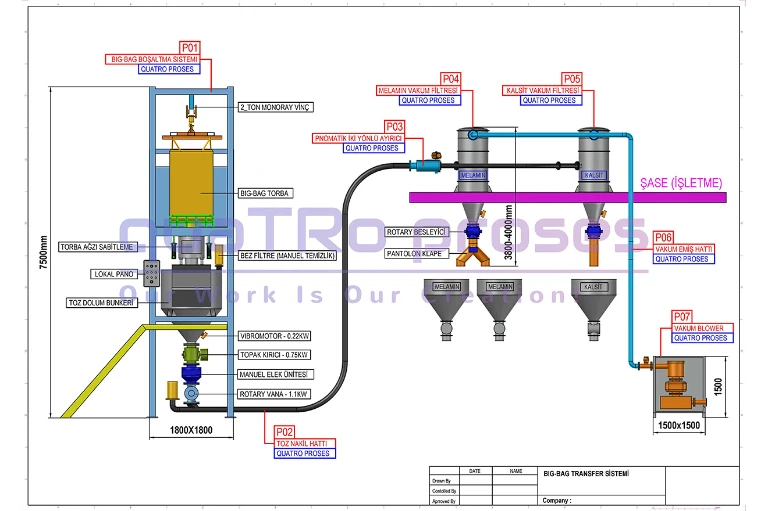

For our mattress manufacturer client’s new investment, our Big Bag Discharge and Pneumatic Conveying System—designed to unload powder raw materials from big bags (FIBC) and pneumatically feed them to the reactors—has been shipped to site.

Operating under vacuum at 6 t/h capacity, calcite and melamine supplied in big bags will be transferred to the respective reactors under PLC control. Positioned inside the plant, the system is engineered with comprehensive dust-control solutions to fully meet Occupational Health & Safety (OHS) requirements.

Scope of supply and services:

- Big bag discharge unit

- DN150 transfer line with large-radius bends

- Melamine vacuum transfer unit

- Calcite vacuum transfer unit

- Mapro roots blower

- PLC automation panel

- Installation and commissioning