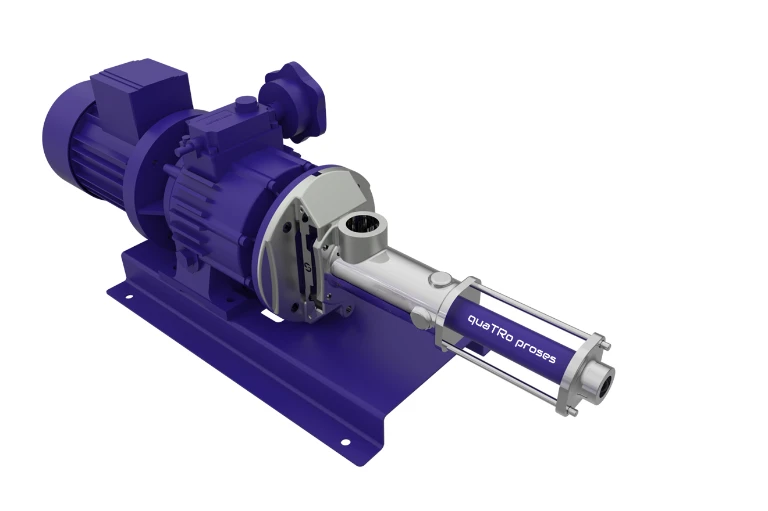

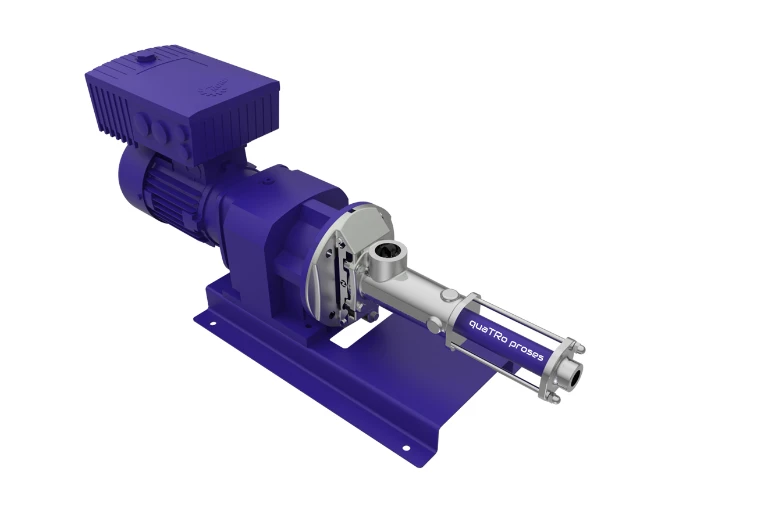

Sydex MonoFlux FLXM

Sydex MonoFlux FLXM Series Progressive Cavity Dosing Pumps

The Sydex MonoFlux FLXM series is designed for precise and stable chemical dosing in industrial processes where repeatability, gentle product handling, and consistent volumetric performance are required. As a progressive cavity (mono) pump, FLXM transfers fluid through sealed cavities formed between the rotor and elastomer stator, providing smooth, near-pulsation-free flow—ideal for dosing applications.

Why FLXM

In dosing duties, even small fluctuations can impact process performance and chemical consumption. The FLXM series supports accurate, controllable dosing across a broad range of fluids and is particularly suitable where standard metering pump technologies struggle with viscosity, lubricity, or shear sensitivity.

Key benefits

Accurate, steady dosing: Volumetric pumping principle supports stable flow and repeatable dosing results.

Low-shear transfer: Suitable for shear-sensitive chemicals and polymer solutions where maintaining product structure matters.

Handles challenging fluids: A practical solution for viscous, abrasive, or solids-containing liquids that can cause issues for diaphragm or centrifugal pumps.

Reduced pulsation and vibration: Helps protect instrumentation and supports more reliable flow measurement and process control.

Serviceable design: Wear parts can be maintained with straightforward procedures, supporting long-term operation.

Typical applications

FLXM dosing pumps are commonly used for:

Water & wastewater treatment: polymer/flocculant dosing, coagulant dosing, pH correction chemicals (where compatible)

Industrial chemical dosing: additives, reagents, and process chemicals

Construction and utilities: admixture dosing and general chemical dosing duties

Mining and process plants: dosing applications requiring stable delivery and robust operation

Performance range

Depending on model and configuration, FLXM pumps cover a wide dosing range and are commonly selected for duties up to approximately 350 L/h, supporting both continuous and intermittent dosing regimes.

Materials and configuration options

Correct material selection is critical for chemical compatibility and service life. FLXM pumps can be configured with suitable wetted-part materials and stator elastomers (e.g., NBR, EPDM, FKM/Viton) based on the chemical, temperature, and operating conditions. Selecting the correct rotor/stator pairing also helps reduce wear and supports stable performance over time.

Selection and integration support

At Quatro Proses, we assist with proper FLXM sizing by evaluating your dosing target, fluid properties (viscosity, solids content, abrasiveness), line pressure, and control philosophy. We also support integration with dosing skids, tanks, mixers, instrumentation, and automation to ensure a reliable and maintainable installation.

Contact us to select the best FLXM configuration for your process and to request a quotation.