Sydex MonoFlux FLXT

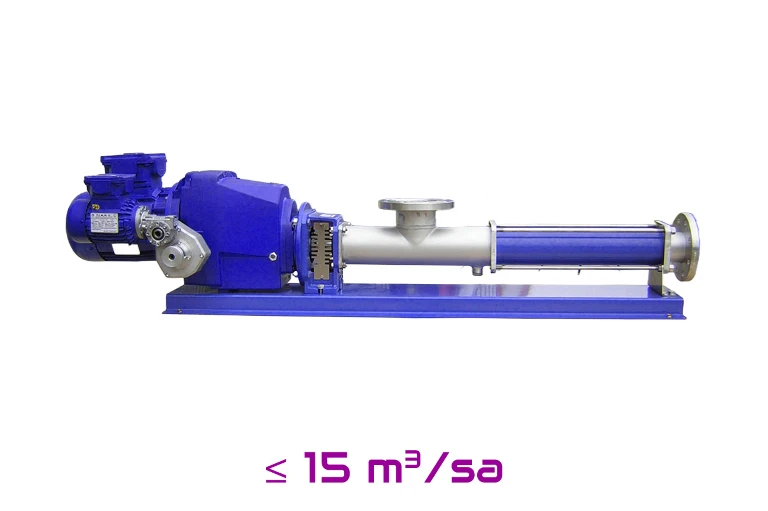

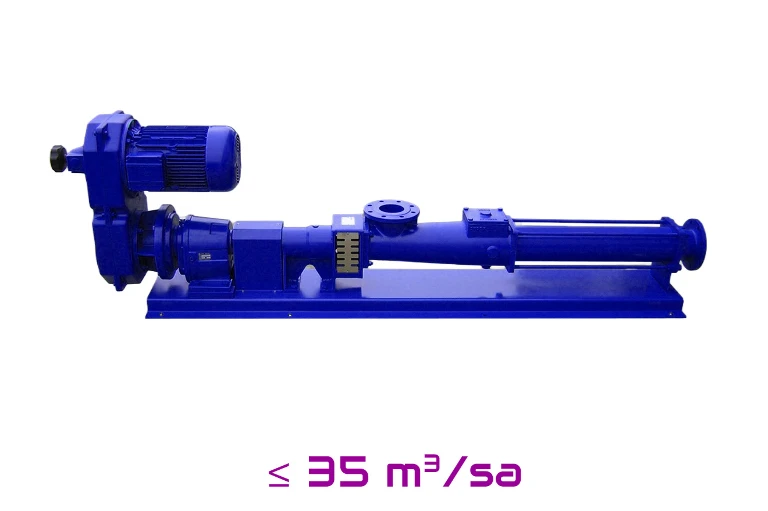

Sydex MonoFlux FLXT Series Progressive Cavity Pumps

The Sydex MonoFlux FLXT series is engineered for the dependable transfer of viscous, abrasive, and solids-laden fluids where steady flow and process stability are critical. As a progressive cavity (mono) pump, the FLXT series moves product through sealed cavities formed by the rotor and elastomer stator, enabling smooth, near-pulsation-free delivery and consistent volumetric performance.

Why FLXT

In many industrial applications, fluid properties change with temperature, shear, or solids concentration. The FLXT series is a strong choice when you need a pump that can handle challenging media while maintaining control and repeatability.

Key benefits

Smooth, stable flow: Supports process control and dosing stability, helping reduce pressure fluctuations and vibration in the line.

Low-shear transfer: Suitable for shear-sensitive products where maintaining fluid structure is important.

Handles difficult media: Designed for viscous and particle-containing fluids; a practical option when centrifugal pumps struggle.

Reliable performance in continuous duty: Built for industrial service with robust construction and serviceable wear parts.

Typical applications

The FLXT series is widely used across industries where consistent transfer and reliable operation are required, including:

Water & wastewater treatment: polymer, sludge, and chemical transfer

Chemical processes: viscous chemicals, additives, and aggressive media (with suitable elastomer selection)

Food and general industry: shear-sensitive or high-viscosity products

Pulp & paper, mining, and utilities: solids-laden streams and process fluids

Performance range

Depending on the selected model and configuration, the FLXT series supports capacities up to 300 m³/h, making it suitable for both transfer and process circulation duties in long or complex piping networks.

Material and configuration options

Selecting the right rotor/stator combination is essential for service life and chemical compatibility. The FLXT series can be configured with appropriate elastomer and component options according to your fluid characteristics (viscosity, abrasiveness, particle size), temperature, and operating pressure.

Selection and integration support

At Quatro Proses, we support you throughout the sizing and integration process from defining duty points and media properties to recommending the appropriate FLXT model and accessories for reliable operation and maintenance-friendly installation.

Request a quote or contact our team to select the best FLXT configuration for your application.